Zymurgy Bob's Distillation Facts

The Difference Between Potstills and Reflux Stills

Although both potstills and reflux stills can be used to distill liquor from the same washes, they do it differently, and usually produce somewhat different liquor.

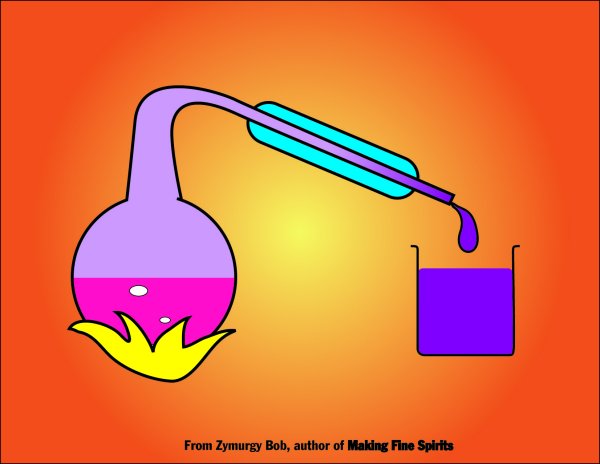

What Does a Potstill Do?

In a potstill, every bit of vapor boiled off the wash goes directly to the condenser, where it is condensed and collected as product. In a potstill, the first, last, and every drop out of the still has exactly the same compounds in it, but in radically varying concentrations. Because of that, the potstill is not good at actually separating the component wash liquids

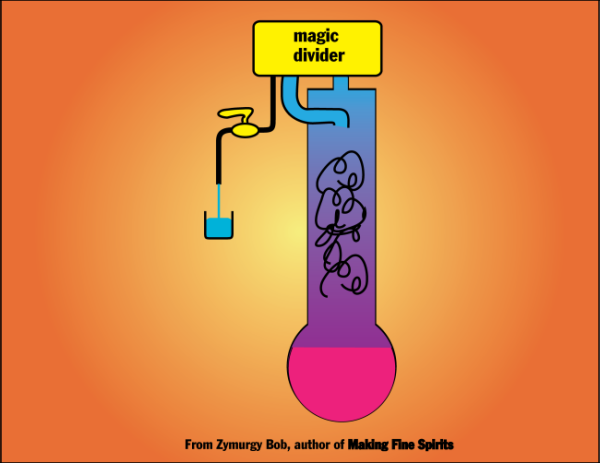

What Does a Reflux Still Do?

The typical hobby reflux still has a boiler at the bottom of a column packed with porous material, and has a reflux condenser at the top of that column. The vapor from the boiling wash travels up through the packing to the reflux condenser, where it is totally (at first) condensed, and the condensed vapor flows back down through the packing as liquid. The vapor going up heats the packing when it condenses and the liquid flowing down cools the packing as it reboils on that now-heated packing.

After some time of the upgoing heating/condensing and downcoming cooling/reboiling, the vapor, liquid, and packing reach a steady state called "equilibrium". In equilibrium, the packing/liquid/vapor at the bottom of the column is at the boiling point of the wash, and the packing/liquid/vapor at the top of the column is the temperature of the lowest-boiling liquid in the wash , and every point in between the top and bottom is at a temperature in between the temperatures of the top and the bottom. At the same time, the concentrations of the liquid wash components have also distributed themselves along the column, with the lighter "heads" liquids at the top of the column. Note that so far no product has been taken out of the still system.

If the heads that you don't want in your liquor are just sitting at the top of the column, it seems that we could just open up the still and collect all those heads to throw away, but that would destroy the equilibrium in the column, and your component liquids would just get mixed right back up again in the column. To get around this, every reflux still has some sort of "magic divider", something that would allow you to sneak off those heads (or any other component) very slowly, while still maintaining the major reflux that keeps the column in equilibrium. There are three basic kinds of magic divider in common hobby use, the cooling management (CM) divider, the liquid management (LM) divider, and the vapor management (VM) divider.

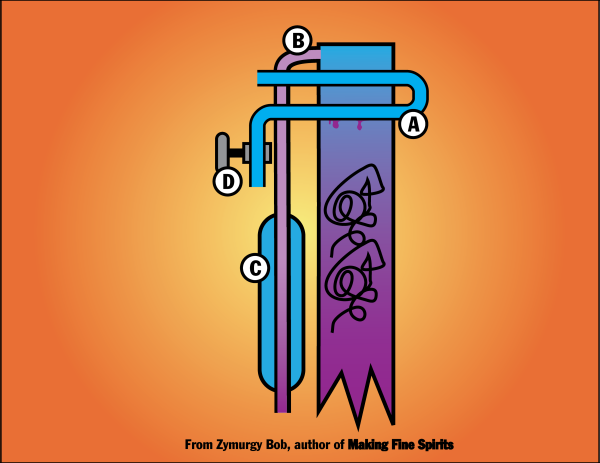

The Cooling Management Reflux Still

In a Cooling Management still the vapor travels up the packed column to the through-tube condenser A where most of the vapor is condensed to drip back down the packed column. The remaining uncondensed vapor passes into the product tube B on the way to the product condenser C. The valve D controls water flow through condenser A, which controls how much vapor is condensed to run back down the column, thereby controlling how much vapor remains uncondensed to get taken off as product.

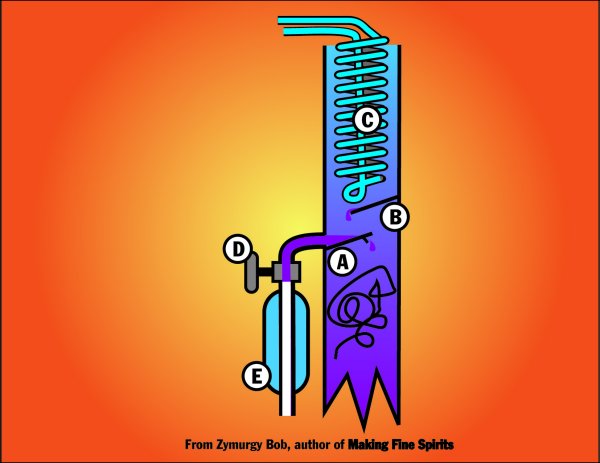

The Liquid Management Reflux Still

In a liquid management reflux still like the Bokakob design illustrated here, the vapor travels up the packed column, past slant plate A and slant plate B to the reflux condenser C, where it is completely condensed. The condensate falls on plate B and a small puddle is trapped on plate A, from which it drips back down the packed column. The valve D controls whether and how much distillate is drawn from thatlittle puddle as product.

E is not a condenser, but simply a cooler for the hot, already liquid distillate.

The Vapor Management Reflux Still

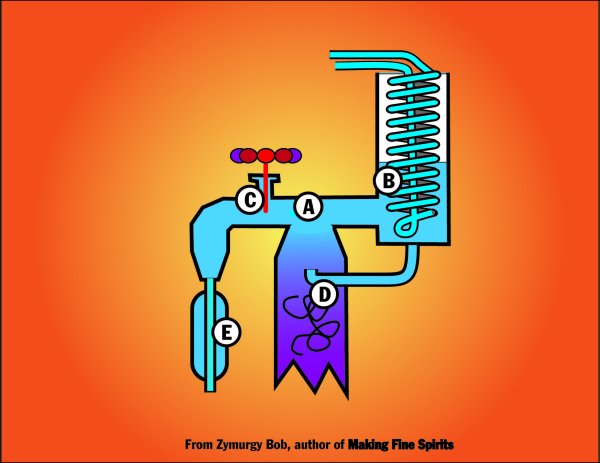

In a vapor management reflux still the vapor travels up the packed column where it is divided at point A. Some vapor goes directly to the reflux condenser B and some goes to the gate valve C. The vapor at the reflux condenser is condensed and the liquid is sent back down to the column in tube D.

The vapor that passes through the gate valve is condensed at the product condenser E and collected as product. In this case, it is the vapor gate valve that controls whether or how much distillate is drawn from the system.

When Do I Use a Potstill, and When Do I use a Reflux Still?

Very generally speaking, when you are doing stripping runs, or distilling full-flavored liquors, the potstill is the appropriate tool. When you are making lighter-flavored spirits, up to and including the lightest-flavored of all, the 95.4% ethanol/3.6% water mixture known as the azeotrope , essentially a vodka concentrate, the reflux still is your obvious choice.

As in everthing else, there are lots of exceptions to these guidelines, like Tito's vodka, excellent, and made in potstills, and fairly decent American whiskeys made in high-production reflux stills, but my guidelines are a good place to start choosing stills.